Hebei Shida Seal Group is a professional manufacturer and supplier of high quality push-on trim seal, sponge bulb and dense rubber with flexible steel wire core, bulb trim seal, rubber door seals for cars, boats, RVs, trucks, and home applications.

Material: EPDM, Ethylene Propylene Diene Monomer Rubber

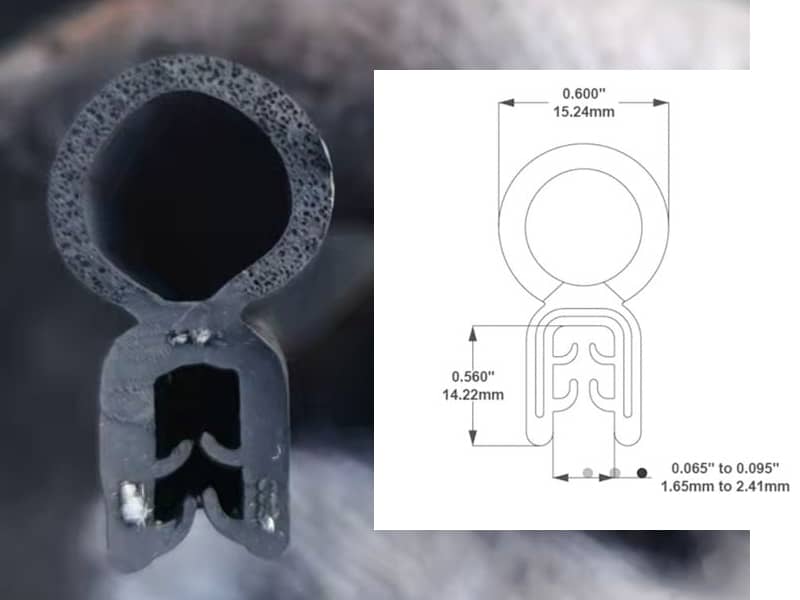

Construction: Sponge Bulb and Dense Rubber with Flexible Steel Wire Core

- Trim Seal: This reliable rubber seal has a compressible top bulb and a bottom trim section that has interior tongues for additional gripping and a steel wire core for impact resistance.

- Medium Durometer: This dual-durometer rubber extrusion consists of a lower-durometer compressible bulb and a higher-durometer retainer section. The softer bulb compresses to create a seal and the harder trim installs over a metal or plastic edge or flange.

- Weather Resistant: EPDM rubber provides environmental sealing and resists sunlight, ozone, oxygen, water, weather, and hot and cold outdoor temperatures. This trim seal is suitable for indoor or outdoor use.

- Endless Applications: It is used in a variety of heavy equipment and transportation applications. Examples include a door seal on agricultural equipment, a door seal for a car, a window seal for a truck, or a hatch seal for an RV or boat.

- Easy-to-install: Press the trim, or retainer, section over the flange or edge by hand. A hand tool such as a rubber mallet can also be used. The gripping tongues help to attach the retainer section to the edge or flange and hold it in place without clips, glue, or fasteners.

Capabilities:

Our facility is fully equipped with the latest extrusion and curing equipment, providing us with the capability to manufacture precision rubber push-on bulb seals in quantities from short run to full production runs. We have the following capabilities:

- Profile sizes from 0.060″- 4.00″ thick and up to 6.00″ width, for a maximum area of 12.00 sq. Inches

- In-house tool design and production, including extrusion dies and splicing molds

- Continuous microwave + hot air cure to provide tighter tolerances, long lengths, shorter cure cycles, and in-line cutting of finished parts

- Precision extrusion of dense materials, simple and complex geometries

- Precision vulcanized splicing, mitered spliced or injection molded corners and joints

- Value-added services, including in-line marking, notching, hole punching, slitting, metal/rubber and plastic/rubber parts assembly.

- Flame resistant trim seals are available upon request.

- Butyl-filled rubber trim seal profiles are available upon request. For increased protection against water leakage and increased adhesion (grip) on the edges. Butyl is non-hardening and elastic and creates an excellent seal under harsh conditions.

Why us?

We understand that the quality of your finished product is dependent on the quality of the components you use. We are committed to manufacturing your part to the highest standard of excellence, so you can be assured that the component will meet or exceed your expectations.

All products are manufactured in accordance with the highest available industry standards to ensure the utmost quality and longevity. Ourrubber bulb trim seals offer a wide choice of available shapes, cost-effective production options, and limited production waste. Our team is eager to use our expertise to provide custom rubber extrusion products that meet or exceed the expectations of our customers.

All products are manufactured in accordance with the highest available industry standards to ensure the utmost quality and longevity. Ourrubber bulb trim seals offer a wide choice of available shapes, cost-effective production options, and limited production waste. Our team is eager to use our expertise to provide custom rubber extrusion products that meet or exceed the expectations of our customers.

Hebei Shida Seal Group is uniquely qualified to manufacture EPDM rubber push-on trim seals for your application. Our quality management system is IATF 16949:2016 accredited. We can provide PPAP Level 3 documents for OEM clients.

We take pride in our ability to deliver custom extruded rubber products to our customers. Please don’t hesitate to get in touch with us regarding your project. You can call send us an e-mail or simply submit a quote.