Hebei Shida Seal Group is an automotive OEM supplier of automotive glass universal mouldings, auto glass weatherstrips, windshield mouldings, vent glass mouldings, original universal “T” mouldings, universal economy underside mouldings, universal reverse/cavity mouldings, universal channel molding with butyl, universal windshield and channel moldings, glass cavity trim molding with butyl seal, universal channel molding with butyl, auto glass push-in EPDM molding with self-adhesive strip, car glass foam underside molding with adhesive, universal feature line trim molding, windshield auto glass universal molding flexible trim rubber, among other extruded rubber products.

Materials:

- Black color EPDM dense rubber with/without pre-applied butyl

- Black color EPDM sponge/foam rubber with/without 3M tape

- Black color PVC/vinyl with/without pre-applied butyl

Universal Windshield and Channel Moldings

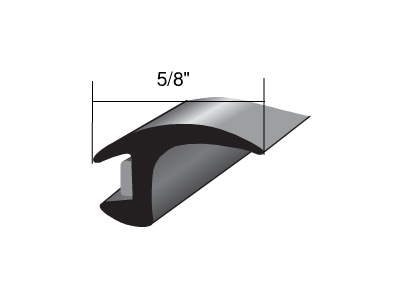

5/8″ Universal Channel Molding With Butyl, EPDM or Vinyl

5/8″ Feature Line Channel Molding with Butyl, EPDM or Vinyl

3/4″ Universal Channel Molding with Butyl, EPDM or Vinyl

3/4″ Feature Line Channel Molding with Butyl, EPDM or Vinyl

1″ Universal “T” Mouldings With Butyl, EPDM or Vinyl

1-1/4″ Universal “T” Mouldings with Butyl, EPDM or Vinyl

5/16″ Universal Underside Molding with Adhesive, EPDM foam

7/32″ Universal Underside Molding with Adhesive, EPDM foam

9/32″ Universal Underside Molding with Adhesive, EPDM foam

3/8″ Universal Underside Molding with Adhesive, EPDM foam

1/4″ Universal Underside Molding with Adhesive, EPDM foam

3/8″ Universal Underside Molding with Adhesive, EPDM foam

1/4″ fin Universal Reverse/Cavity Mouldings, Vinyl

3/8″ fin Universal Reverse/Cavity Mouldings, Vinyl

3/8″ fin Universal Reverse/Cavity Mouldings, EPDM

1/4″ fin, 5/8″ overall width Universal Reverse/Cavity Mouldings, EPDM

Our glass channel universal mouldings are resistant to UV rays, oxidants, and severe weather conditions, allowing them to always remain flexible even on the coldest winter day. They will not shrink or discolor, will never crimp around corners, always lay flush against the vehicle, and never need a heat gun to install because they stay flexible. A thin layer of butyl inside the channel firmly adheres the moulding to the edge of the glass holding the moulding in place.

- Do not shrink or discolor over time

- Stay on without tape

- Never crimp around corners

- Always lay flush against the vehicle

- Fit both thick windshields and thin tempered parts

- Just several mouldings will fit thousands of applications

Our facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision automotive glass universal rubber mouldings in quantities from short run to full production runs. We have 5 extrusion lines, continuous cure microwave, precision cutting, and splicing machines, and also provide value-added finishing services. In addition, we offer in-house tool, die, and mold design and manufacturing to ensure that your parts are manufactured to the most exacting requirements.

Hebei Shida Seal Group focuses on good design, lasting solutions and rubber moldings innovation. We help you developing individual solutions regardless the size of your project and across all industries. Common to our solutions is our focus on you and your specific needs. The goal is to provide you with competitive benefits and visible results.

We take pride in our ability to deliver custom and standard rubber mouldings to our customers. Please don’t hesitate to get in touch with us regarding your project. You can call send us an e-mail or simply submit a quote.