What Is Dual Durometer Rubber Extrusions?

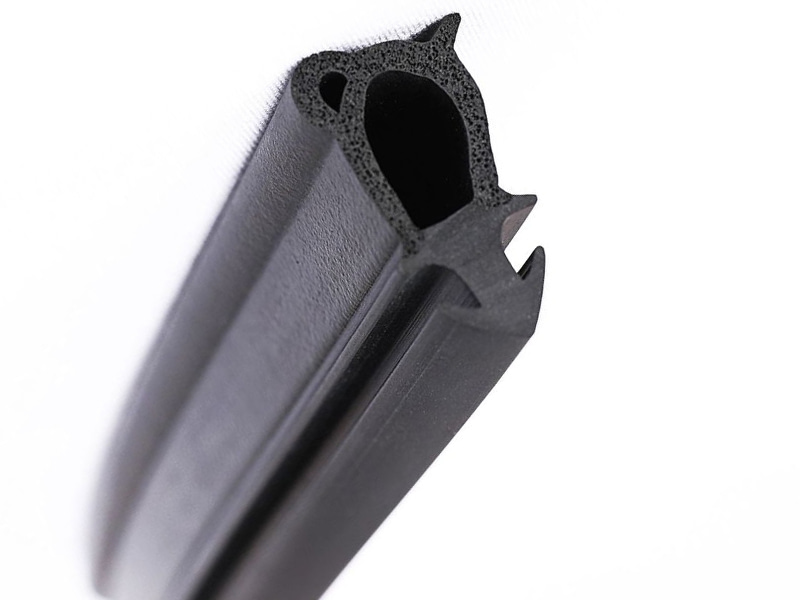

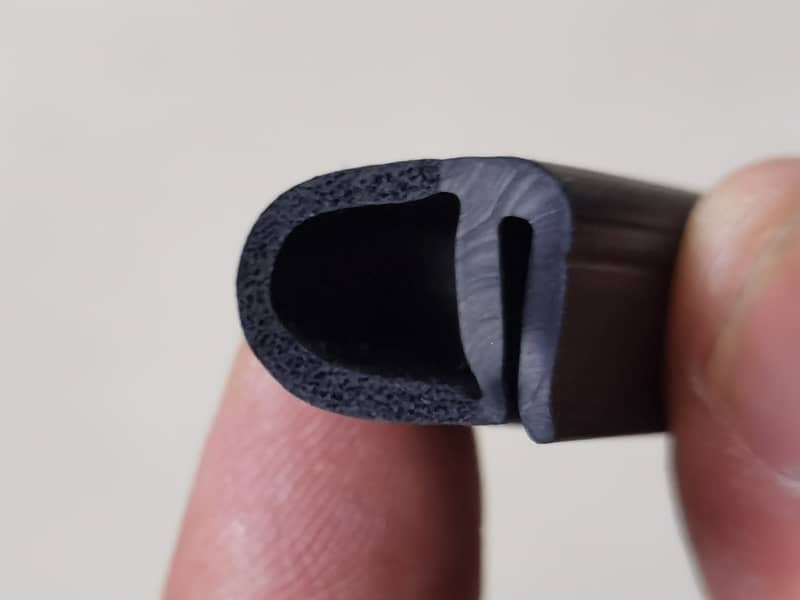

It is a co-extrusion process that fuses two materials of different physical properties into one uniform or consistent cross section. The most common of these extrusions is the combination of a rigid material, for strength, with a soft or flexible material, for function, into various one-piece profiles.

What Are The Advantages Of Dual Durometer Rubber Extrusions?

By joining two materials of different physical properties, structural integrity and flexible function can be combined into one part. For example, when a rubber gasket must be attached to a metal part to provide a closure seal, a dual durometer rubber extrusion combines both functions into one piece, which significantly reduces assembly costs while enhancing performance and function.

Purpose And Application

Dual durometer extrusions can serve a variety of purposes. Most often, the harder material serves as means of attachment, and the softer compound completes the seal. Sometimes, however, co-extruding polymers is done for cosmetic purposes. There are many ways to get creative when designing a seal— using multi-color, multi-durometer, notches, holes and PSAs. You can mix and match, or, put them all into one package. Contact us today and get more information and let us help start on your new project.

About Us:

About Us:

Hebei Shida Seal Group is a leading manufacturer of Co-extruded Dual Durometer Sponge and Solid Rubber Extrusions and molded rubber parts from Qinghe, Hebei, China.

With combined experience within the industry, we have developed the talent, technical knowledge, engineering expertise and equipment to manufacture Special Profiles meeting the most stringent specifications. Our in-house tool and mould making as well as state-of-the-art development, manufacturing and testing methods ensure a maximum of product quality and reliability.

Capabilities:

- Certified to IATF (International Automotive Task Force) 16949

- Certified to ISO 14001 and ISO 45001 (Environment, Health and Safety)

- Production area 40,000 m²

- Processing of: EPDM Dense and Sponge, CR, NBR

- 5 continuous vulcanization (microwave + hot air ) extrusion lines

- 2 components extrudable

- 3 components extrudable

- Cutting and punching machines for precise lenghts

- Injection presses for mould corners

- Film vulcanization for corners and rings

Main Products:

- Custom EPDM Rubber Extrusions

- Automotive Weatherstripping, Door Seals, Window Seals

- Edge Trims & Seals,Self-Sealing Weatherstrips

- EPDM rubber mouldings

- Molded Rubber Bellows, Dust Covers

- Engineered TPV/TPE Profiles

- Co-extruded Trim Seals (dual durometers with a Metal Core, Segmented Steel or Wire Carrier)

Contact Us:

If your applications require Dual Durometer Rubber Extrusions and Coextruded Rubber Profiles, please feel free to contact us. We are committed to supplying our customers with robust rubber components and outstanding services.