China Custom TPV Extrusions, Extruded Thermoplastic Vulcanizates Profiles Manufacturer

As a leading manufacturer of custom TPV (Thermoplastic Vulcanizates) Extrusion in China, Hebei Shida Seal Group offers a variety of extruded weather seals, gaskets, tubes, profiles from Thermoplastic Vulcanizates.

WHAT IS TPV?

Thermoplastic vulcanizates (TPV) are thermoplastic elastomers that combine the characteristics of vulcanized rubber with the processing properties of thermoplastics. It exhibits many of the properties found in EDPM, and is compounded by encapsulating EDPM rubber particles in a polypropylene (PP) matrix. Specific properties of TPV include good compression and tension properties, chemical resistance, resistance to temperature extremes, dimensional stability, and durable performance.

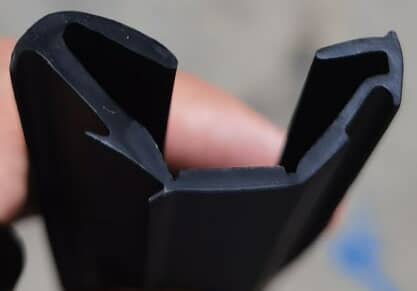

TPV is used for applications in the construction, automotive, appliance, electrical, and medical device industries. Some of the custom TPV extrusions we manufacture are:

TPV is used for applications in the construction, automotive, appliance, electrical, and medical device industries. Some of the custom TPV extrusions we manufacture are:

- Weather seals

- Gaskets

- Trims

- Glass Run Channels

TPV ADVANTAGES

TPV provides a good balance of tensile strength, tear resistance, low temperature flexibility, and weatherability. Available as a natural colored, colorable compound.

We utilize sustainable, environmentally-responsible manufacturing practices, to minimize waste and maximize energy efficiency in our manufacturing. We can assist you in selecting environmentally friendly alternatives or compounds for your project.

We always manufacture our TPV plastic extrusion profiles from the highest quality compounds available. This ensures that our TPV parts are not only suitable for use, but also made to last. Despite offering high strength and tear resistance, our TPV products are also highly flexible. This enables our profiles to fit around a wide variety of curves.

Why Choosing Hebei Shida Seal Group?

We always manufacture our TPV Extrusions from the highest quality compounds available. This ensures that our TPV Extrusions are not only suitable for use, but also made to last. Despite offering high strength and tear resistance, our TPV Extrusion seals are also highly flexible. This enables our profiles to fit around a wide variety of curves.

Our facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision extruded TPV Extrusions in quantities from short run to full production runs. We have 5 extrusion lines, continuous cure microwave, precision cutting, and splicing machines, and also provide value-added finishing services. In addition, we offer in-house tool, and mold design and manufacturing to ensure that your TPV Extrusions are manufactured to the most exacting requirements.

Hebei Shida Seal Group is uniquely qualified to manufacture TPV Extrusions for your application. Our quality management system is IATF 16949:2016 accredited. We can provide PPAP Level 3 documents for OEM clients.

Hebei Shida Seal Group is uniquely qualified to manufacture TPV Extrusions for your application. Our quality management system is IATF 16949:2016 accredited. We can provide PPAP Level 3 documents for OEM clients.

If you want to contact us about any issue please call (+86)319 8032626 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.

About Us:

Hebei Shida Seal Group is a leading manufacturer of TPV Extrusions, Vertical Bulb Trim Seals, Co-extruded Dual Durometer Sponge and Solid Rubber Extrusions with Flexible Wire Core 75001360, rubber strips, rubber seals, extrusions, rubber gaskets, extruded rubber parts and molded rubber parts from Qinghe, Hebei, China.

With combined experience within the industry, we have developed the talent, technical knowledge, engineering expertise and equipment to manufacture Special Profiles meeting the most stringent specifications. Our in-house tool and mould making as well as state-of-the-art development, manufacturing and testing methods ensure a maximum of product quality and reliability.

Capabilities:

- Certified to IATF (international Automotive Task Force) 16949,

- Certified to ISO 14001 and ISO 45001 (Environment, Health and Safety)

- Production area 40,000 m²

- Processing of: EPDM Dense and Sponge, CR, NBR

- 5 continuous vulcanization (microwave + hot air ) extrusion lines

- 2 components extrudable

- 3 components extrudable

- Cutting and punching machines for precise lenghts

- Injection presses for mould corners

- Film vulcanization for corners and rings

Main Products:

- Custom EPDM Rubber Extrusions

- Automotive Weatherstripping, Door Seals, Window Seals

- Edge Trims & Seals,Self-Sealing Weatherstrips

- Window Channels, Flocking and Urethane Slip-coating

- Engineered TPV/TPE Profiles

- Co-extruded Trim Seals (dual durometers with a Metal Core, Segmented Steel or Wire Carrier)

Contact Us:

If your applications require TPV Extrusions, EPDM Trim Seals, Rubber Profiles, Extruded Rubber Gaskets, and Seals, please feel free to contact us. We are committed to supplying our customers with robust rubber components and outstanding services.