EPDM Rubber Edge Trim with Metal Core, Rubber Extrusion and Rubber Seals Meeting FMVSS 302

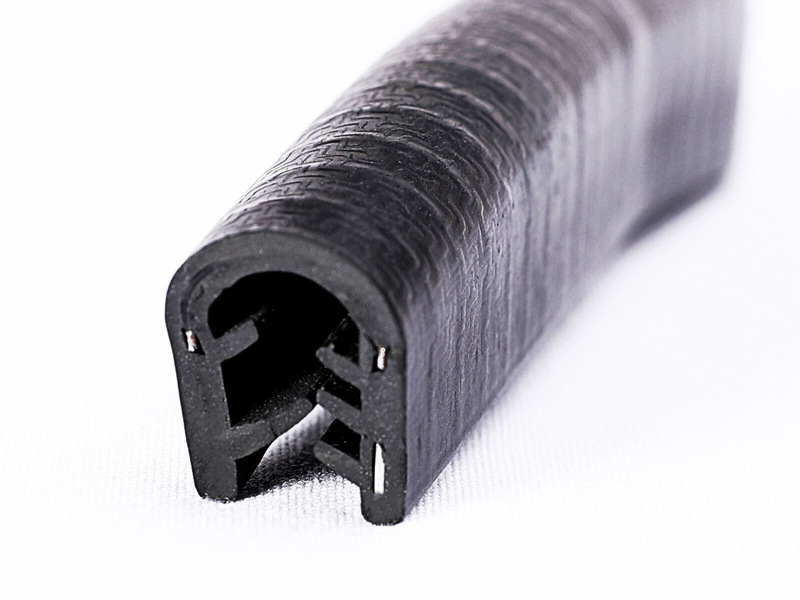

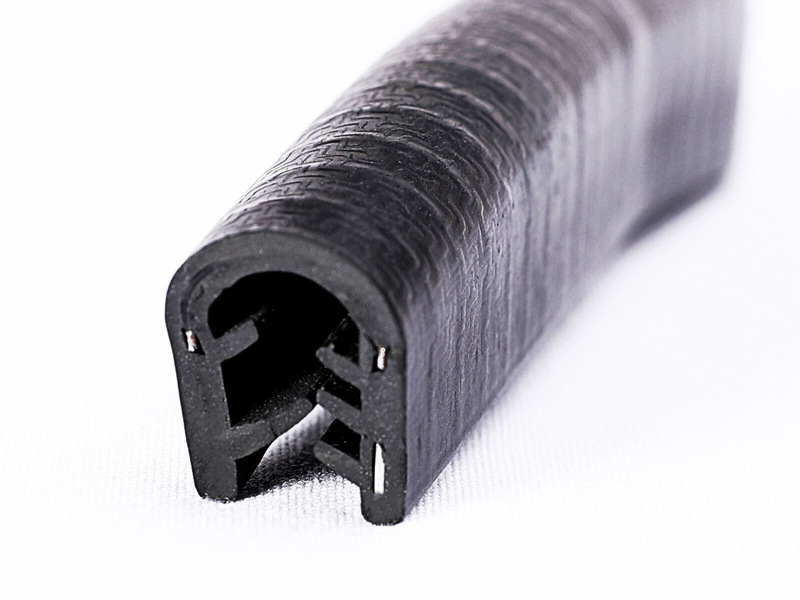

Hebei Shida Seal Group is a leading manufacturer of EPDM rubber edge trim with metal core, rubber extrusions and seals for a wide range of industries. EPDM rubber Edge trim is used to protect personnel, vehicles, machinery, and equipment. Applications include vehicle doors, truck cabs, machine guards, and equipment cabinets. Rubber edging is designed to be pushed into place over a flange.

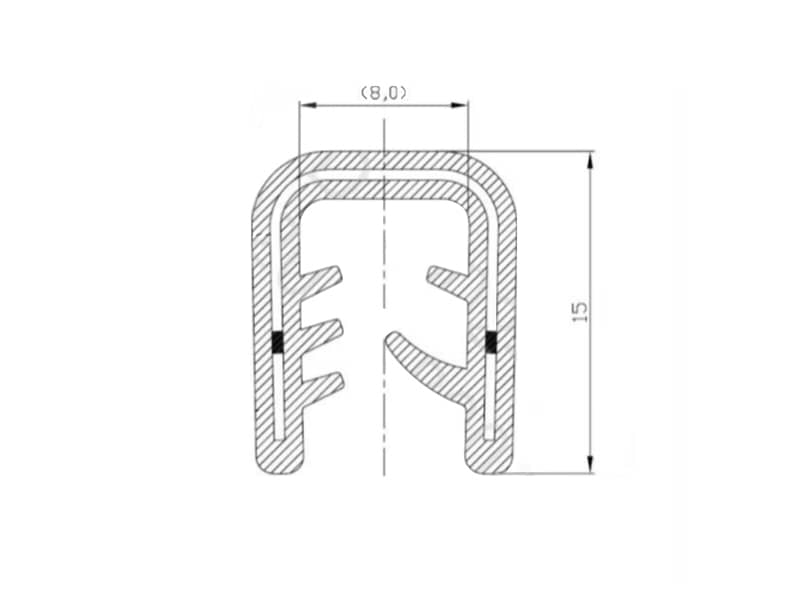

To help the rubber seal absorb impact, edge trim contains a metal core, which adds strength and stability, making this trim more durable than standard rubber trim.

Made of EPDM, it resists abrasion better than plastic trim. It also resists UV, ozone, and chemicals. Use this trim to protect the edges of panels, boards, signs, and mirrors from impact. Push it onto an edge and it grips on three sides for a tight hold. All of this trim is flexible so it can bend along a gradual curve. It has a hard rating to withstand high levels of impact. It’s nonmarking and can be used outdoors. Meets FMVSS-302 for Federal Motor Vehicle Safety Standards for flammability.

EPDM Rubber Edge Trim Features:

EPDM Rubber Edge Trim Application:

EPDM Rubber Edge Trim Application:

We always manufacture our Extruded EPDM Rubber Edge Trims from the highest quality compounds available. This ensures that our EPDM Rubber Edge Trims are not only suitable for use, but also made to last. Despite offering high strength and tear resistance, our window seals are also highly flexible. This enables our profiles to fit around a wide variety of curves.

Our facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision EPDM Rubber Edge Trims in quantities from short run to full production runs. We have 5 extrusion lines, continuous cure microwave, precision cutting, and splicing machines, and also provide value-added finishing services. In addition, we offer in-house tool, and mold design and manufacturing to ensure that your parts are manufactured to the most exacting requirements.

Hebei Shida Seal Group is uniquely qualified to manufacture custom EPDM Rubber Edge Trims for your application. Our quality management system is IATF 16949:2016 accredited. We can provide PPAP Level 3 documents for OEM clients.

If you want to contact us about any issue please call (+86)319 8032626 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.

Keywords: rubber edge protector for metal, rubber guards for sharp edges, push on rubber edge trim, rubber step edge protector, rubber edge guard for metal, sharp edge rubber trim, rubber edge protector strips, rubber cover for metal edge, rubber trim for metal edge,, rubber edge trim molding, rubber edge trim seals, rubber or vinyl edge trim, flexible rubber edge trim, sharp edge rubber trim, push-on rubber edge trim, u shaped rubber edge trim.

EPDM Rubber Edge Trim Application:

EPDM Rubber Edge Trim Application: