EPDM rubber – Ethylene propylene diene monomer rubber is a terpolymer. It is obtained from ethylene-propylene-diene monomers. This rubber is produced by the action of the third monomer. It is cross-linked in the process of sulfur or peroxide vulcanization.

What does EPDM stand for?

EPDM abbreviation comes from the English language. It stands for ethylene propylene diene monomer (rubber), i.e. ethylene propylene diene rubber.

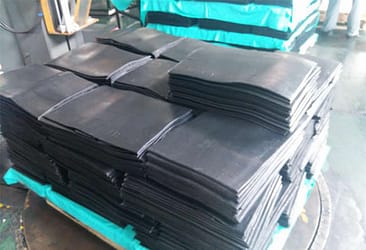

Fire Retardant EPDM Rubber Compounds

EPDM – Properties

EPDM rubber has an exceptionally good ability to reverse deformation under the influence of mechanical forces. The deformation is created while maintaining the structure of the continuity of the material. This property does not change, even in the face of temperatures up to +110 degrees. EPDM rubber remains flexible even in a collision with a temperature of 40 degrees below zero.

EPDM temperature range

The most common use of a rubber compound with EPDM is for the following temperature range:

-40 ° C to + 110 ° C

It is worth noting that the offer for specialist O-rings available at POWER Rubber includes EPDM O-rings resistant up to +150 °C

EPDM Resistance

Ethylene-propylene-diene rubber is also characterized by many properties and good resistance to many factors, such as:

Ethylene-propylene-diene rubber is also characterized by many properties and good resistance to many factors, such as:

- Hot water and steam up to +150 degrees. Celsius, and in the case of special materials up to +180 Degrees

- Brake oils based on glycol up to 150 Degrees

- Organic and inorganic acids

- Basics: potassium and sodium, and cleaning agents

- Hydraulic fluids based on phosphate esters

- Silicone based oils and greases

- Polar solvents such as ketones, esters and alcohols

- Skydrol – 500 and 7000

- The action of ozone and UV radiation

- Weathering of aging

- It does not discolor or stain other materials

Moreover, EPDM rubber is distinguished by its low elasticity. Hence, it is also resistant to abrasion compared to other types of rubbers.

However, ethylene-propylene-diene rubber is not resistant to the action of:

- Products based on mineral oils such as greases, oils and fuels

- Aliphatic, aromatic and chlorinated hydrocarbons

Application of EPDM

Thanks to its wide range of properties, ethylene-propylene-diene rubber has been used in many industries and industries. In the automotive production, he is responsible for creating seals for windows and doors, shock-absorbing elements and for construction. Including sealing profiles for plastic joinery, hydraulic hoses, cable covers and roofing.

In the automotive industry, it is also used for the production of tires, tubes, bumpers, etc. With its help, surfaces are also created for the so-called safe playgrounds. Valued in the water installation industry. It is used for sealing in the food industry. Compounds based on EPDM rubber are used in the production of automatic washing machines.

Thanks to its use, elements for shock-absorbing and damping vibrations are also created. Ethylene-propylene-diene rubber is especially valued primarily in the insulation of roofs and terraces. Thanks to the use of EPDM, roofs and terraces are guaranteed water-tightness and safety.

About Us:

Hebei Shida Seal Group is a leading manufacturer of flame-resistant weather-resistant EPDM rubber strips, EPDM rubber seals, EPDM rubber extrusions, EPDM rubber profiles, EPDM rubber gaskets, extruded EPDM rubber parts and molded EPDM rubber parts from Qinghe, Hebei, China. With combined experience within the industry, we have developed the talent, technical knowledge, engineering expertise and equipment to manufacture rubber extrusions meeting the most stringent specifications. Our in-house tool and mould making as well as state-of-the-art development, manufacturing and testing methods ensure a maximum of product quality and reliability.

Capabilities:

Capabilities:

- Certified to IATF (international Automotive Task Force) 16949,

- Certified to ISO 14001 and ISO 45001 (Environment, Health and Safety)

- Production area 40,000 m²

- Processing of: EPDM Dense and Sponge, CR, NBR

- 5 continuous vulcanization (microwave + hot air ) extrusion lines

- 2 components extrudable

- 3 components extrudable

- Cutting and punching machines for precise lenghts

- Injection presses for mould corners

- Film vulcanization for corners and rings

Main Products:

- Custom Rubber Extrusions and Profiles

- Automotive Weatherstripping, Door Seals, Window Seals

- Edge Trims & Seals,Self-Sealing Weatherstrips

- Window Channels, Flocking and Urethane Slip-coating

- Engineered TPV/TPE Profiles

- Co-extruded Trim Seals (dual durometers with a Metal Core, Segmented Steel or Wire Carrier)

Contact Us:

If your applications require Flame-Resistant EPDM Rubber Strips, please feel free to contact us. We are committed to supplying our customers with robust rubber components and outstanding services.