Hebei Shida Seal Group is a custom molder of EPDM Flange Gaskets, EPDM rubber seals and all types of molded rubber parts for a wide range of industries.

Steam-Resistant EPDM Flange Gaskets

Steam-resistant flange gaskets are made of EPDM (ethylene propylene diene monomer) which is a synthetic rubber that is resistant to chemicals, steam, and water. They are often used in heating systems for chemical plants and refineries.

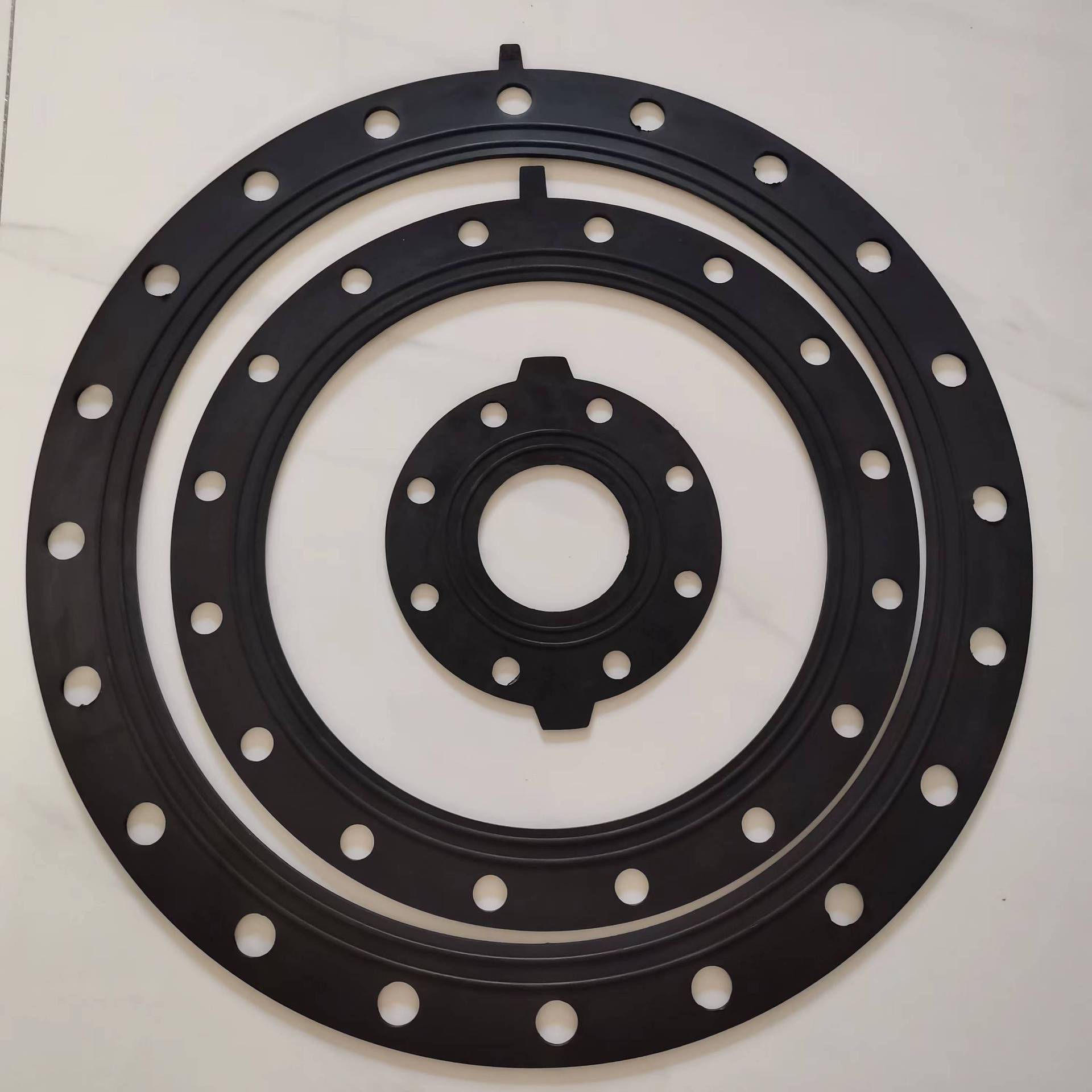

EPDM Full-Face Gaskets

EPDM full-face gaskets cover the entire surface area of the flange and include holes to insert flange bolts and ease alignment. The gasket extends to the outside diameter of the flange which prevents dirt and contaminants from entering the joint. These gaskets are typically used with flat-face (FF) flange fittings so that the mating flange components fit flush against the gasket. Full-face gaskets require the joint to be disassembled to install.

EPDM Ring Gaskets

EPDM ring gaskets sit against the internal edge of the flange, around the pipe bore, and inside the bolts. They are typically positioned onto the raised surface of a raised-face (RF) flange. Ring gaskets install by dropping them into the flange fitting without fully disassembling the joint.

About Us

Capabilities:

- Elastomer compounds: EPDM, NBR, VMQ (Silicone)

- A vast range of sizes available (standard and Non-standard sizes).

- Hardness Shore A in a range of 55 to 85.

- Tested and approved compounds for various applications.

- Low tooling costs.

- Press sizes range from 50 ton to 300 ton.

- Excel in both simple and complex projects.

- Supply in both high and low volume quantities.

- Capabilities to supply PPAP and process control documentation.

- In-house custom compound formulating, and mixing capabilities.

Industries:

- Industrial Equipment

- Transportation

- Automotives

- Electrical and Electronics

- Agriculture and Forestry Machines

- Gardening Tools

- Water System

- Medical Industry

- Home Appliance

- Military and Aerospace

Our IATF 16949:2016 certified facility is fully equipped with the latest equipment and technology, providing us with the capability to manufacture precision molded rubber parts in quantities from short run to full production runs. We have 60 vulcanizing presses and also provide value-added finishing services giving us the capability to deliver a diverse set of parts for a wide range of industries, including aerospace, agriculture, automotive, industrial machines, HVAC, and many others. In addition, we offer in-house tool and mold design and manufacturing to ensure that your parts are manufactured to the most exacting requirements.

We are committed to manufacturing your rubber molded parts to the highest standard of excellence so you can be assured that your component will meet or exceed your expectations.

If you want to contact us about any issue please call (+86)319 8032626 or send us an e-mail. If you would like to submit a proposal for consideration simply submit a quote.