Rubber is by nature a solid material. It only deforms when it is pressed, which requires high compressive forces. Yet there is one type of rubber that is easily deformable: foam rubber. Cellular rubber is a particularly versatile variant of this.

It is quite possible that you are not yet familiar with the advantages of cellular rubber. Foam rubber, on the other hand, is already a well-known phenomenon. For example, it is widely used in the packaging industry. The material is therefore widely applicable and has a number of fine properties. This also applies to cellular rubber. Discover in this article what cellular rubber can do for your company!

Cellular rubber: a handy type of foam rubber

Celullar rubber is a type of foam rubber. This means that it has a cell structure. This is in contrast to normal rubber, which has no cell structure. Just like foam rubber, cellular rubber is a light material and is compressible. Cellular rubber also has a number of fine properties. They are listed below.

- Very light;

- Compressible;

- Dustproof;

- Waterproof;

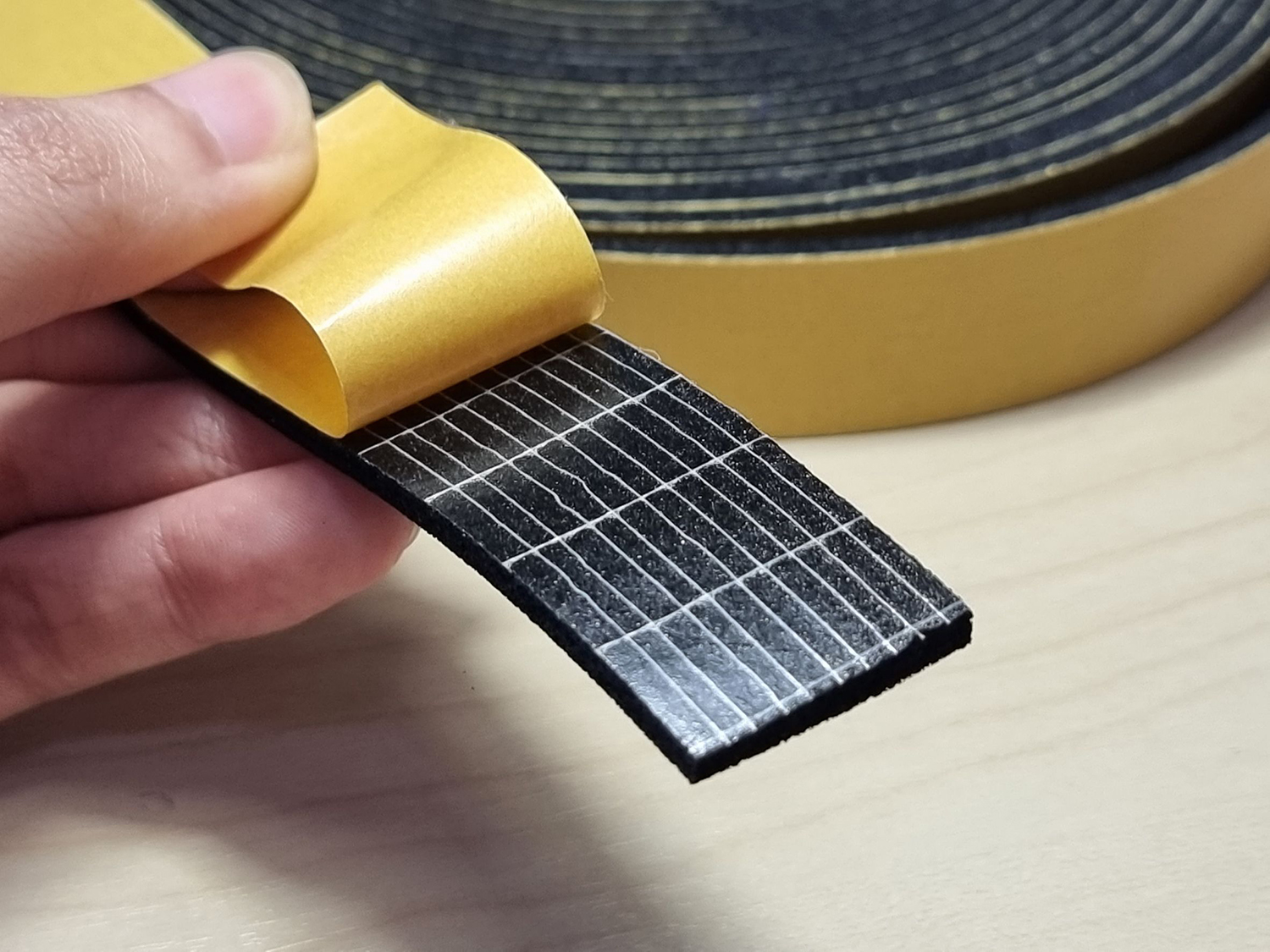

- Self-adhesive layer;

- Low compressive force required.

Open cell rubber

Cellular rubber is not made by extrusion. What does the production process look like then? First of all, a mould is used to make blocks of cellular rubber. These blocks are cut into sheets. During this process, the skin is cut off. These sheets are then cut back into strips. Cellular rubber owes its coarse, open structure to this. The cells are literally cut through the middle.

Cellular rubber can be compared to a cake: the outside is crispy, but the inside is soft. This so-called crust is called a skin in cellular rubber. However, this is removed during the production process. What remains is an open cell structure.

Main groups

Cellular rubber is made of different materials. These can be divided into four main groups.

- Well-known rubber materials such as NBR, EPDM and Neoprene.

- Polymer ethane foams.

- Polyethylene foams.

- Silicones. On the basis of the hydrogen chain this is not a rubber. However, it is usually classified as ‘rubber’.

Cellular rubber or sponge rubber?

Cellular rubber and sponge rubber are both foamed materials. They therefore fall under the term ‘foam rubber’. The two materials are sometimes mixed up. However, there are differences between the two materials.

Cellular rubber

Cellular rubber consists of closed cells. This means that the cells are not connected to each other. This makes cellular rubber completely impenetrable. The original blocks have a skin. However, this skin disappears when the blocks are cut to size. This does not affect the impermeability. Cellular rubber is cheaper than sponge rubber and also lighter. However, there are limited colour possibilities.

Sponge rubber

Sponge rubber consists of open cells. Sponge rubber does have a skin as a result of the production process. This skin functions as a sealing layer. An example is a sponge with which the windows are soaped. This sponge absorbs moisture, but can also lose that moisture if it is squeezed. Sponge rubber is heavier and more expensive than cellular rubber. However, more colours and shapes are possible here.

The applications of cellular rubber

The great advantage of cellular rubber is that you can quickly create a seal with low pressure. It is a dense material and yet it is compressible. It can be used to bridge large spaces or gaps. Cellular rubber is ideal in situations where you want to press the rubber 50-80%. This is common in the construction industry, where structures are not always accurate enough.

Some concrete examples where cellular rubber is often used:

- Window, door and hatch seals (insulation material)

- Lighting hoods

- Electricity connections

- Air handling equipment (air conditioners)

- Noise installations (attenuation)

What are the alternatives of cellular rubber?

Should you always choose cellular rubber? No, that’s not the case. It depends on the situation which type of seal is most suitable. In some cases it is solid rubber. In other cases, sponge or cellular rubber is the right choice.

Solid rubber

Solid rubber is recommended if high compressive forces can be applied to the construction. Think, for example, of products that are cleaned with a high-pressure sprayer. In that case, solid rubber is always a better choice than cellular rubber. In the long term, solid rubber is also more durable. It contains more material and “memory”, which ensures a better seal.

Sponge rubber

Does hygiene play an important role in the product? For example, because it is used in the medical sector? Then sponge rubber is preferable to cellular rubber. Cellular rubber is difficult to clean because of its open cell structure. Sponge rubber, on the other hand, has a skin. That makes it more hygienic.

Cellular rubber

As said, cellular rubber has a few concrete advantages. It is ideal for situations where a low pressure force is required. The material is compressible and also water and dust tight. This makes it a popular sealing material for sound systems and air conditioning systems, for example. Moreover, it is a relatively inexpensive material. So with cellular rubber you can go in all directions. Discover for yourself the advantages of this versatile type of foam rubber!