The basic rubber molding processes we utilize are compression molding and injection molding.

Compression Molding:

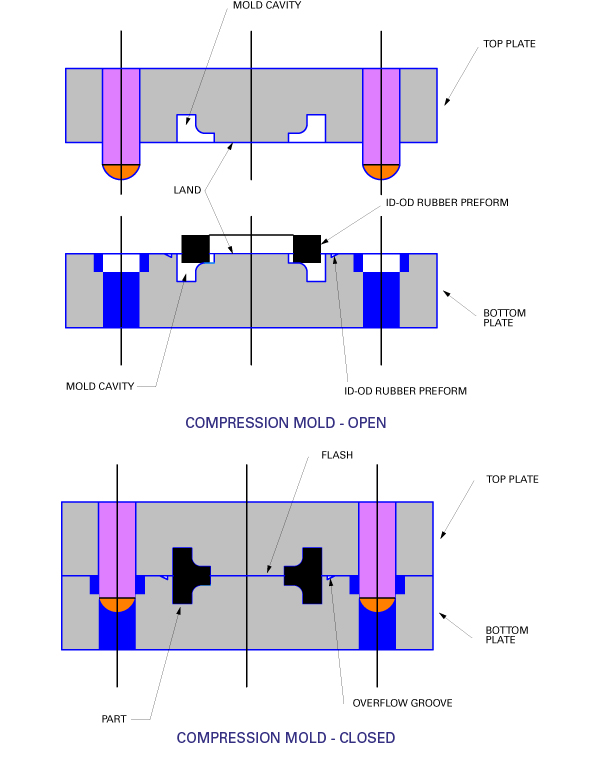

Compression molding is a process that involves taking a rubber compound or mixed raw material and creating “pre-forms” in the basic shape of the end product. The pre-forms provide a surplus of material to be placed in the cavity, thus ensuring a total cavity fill. Once in place, the mold is then closed, applying both heat and pressure to the pre-form and allowing it to fill the cavity. When the cavity is filled, excess pre-form material spills out into overflow grooves. Following this step the rubber is then demolded, usually by hand, leaving us with the molded rubber product.

Compression Molding Diagram

Compression molding is often chosen for medium hardness compounds in low volume production or in applications requiring particularly expensive materials. This process helps to minimize the amount of overflow, or flash created during the rubber molding process.

In creating compression molded rubber products, the pre-forms can be difficult to insert into more complex mold designs. Furthermore, the compression molding process does not lend itself well to the material flow requirement of harder rubber compounds.

Benefits of Compression Molding:

- Cost effective tooling

- Maximized cavity count

- Economical process for medium precision

Compression molding can be a cost effective solution in situations where:

- The tooling already exists

- The cross-section of the part is very large and requires a long cure time

Applications of compression molding range from simple rubber grommets to complex air intake hoses, Hebei Shida Seal Group can offer a variety of other molded rubber products through compression molding.

Injection Molding:

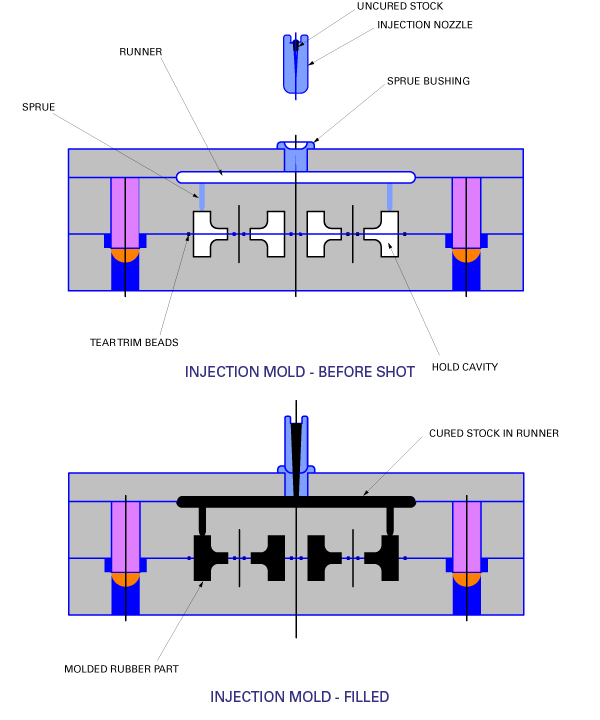

This process is the most efficient way to mold rubber in most cases. Injection and injection-transfer molding start with more efficient material preparation. The material is mixed, typically in 500-pound batches, and then stripped immediately after being mixed, into continuous strips measuring approximately 1.25″ wide and 0.375″ thick. This strip is fed into a screw on the injection molding machines, which charges a barrel as needed with a pre-defined amount of material. When the mold is closed, the material in the barrel is injected into the mold cavities and cured.

Injection Molding Diagram

Advantages of injection molding:

- The complete elimination of pre-forms

- The production and need for pre-forms is a labor intensive step that can potentially affect the finished product through variability in pre-form weight and shape.

- Elimination of operator placement of pre-forms.

- Since pre-forms are eliminated, the need for operators to place the pre-forms in a cavity (compression molding) or pot (transfer molding) is removed.

- Injection screw pre-heats material before forcing it into cavities

- This process decreases the viscosity of the material, allowing it to flow more easily into the cavities.

- This pre-heating provides the potential for decreased cure times through

- More rapid cavity filling due to lower viscosity

- Material already being in the curing process through the heat added during screw charging and shear created during injection

- Reduced cycle time

- Flashless tooling

- Economical process for high volumes of medium to high precision components

- Capable of producing overmolded components

- Minimal material waste

About us:

Hebei Shida Seal Group is an ISO/TS 16949 accredited manufacturer of molded rubber products and extruded rubber products from Hebei, China. We are tier-2 supplier to Hyundai and Kia. Look no future than Hebei Shida Seal Group if you need molded rubber products of high quality!